LIPOPROTEIN LIPASE from Pseudomonas sp.

LPL-311

Triacylglycero-protein acylhydrolase (EC 3.1.1.34)

Triglyceride + 3H₂O ► Glycerol + 3Fatty acid

| Appearance: | Light brown amorphous powder, lyophilized | ||

|---|---|---|---|

| Activity: | GradeⅢ 20U/mg-solid or more (containing approx. 80% of stabilizers) |

||

| Contaminants: | Phosphatase ≤1.0×10⁻³% Catalase ≤2.0×10⁻²% NADH oxidase≤1.0×10⁻³% Cholesterol oxidase ≤2.0×10⁻³% |

||

| Stabilizers: | Mg⁺⁺, Na-cholate, BSA | ||

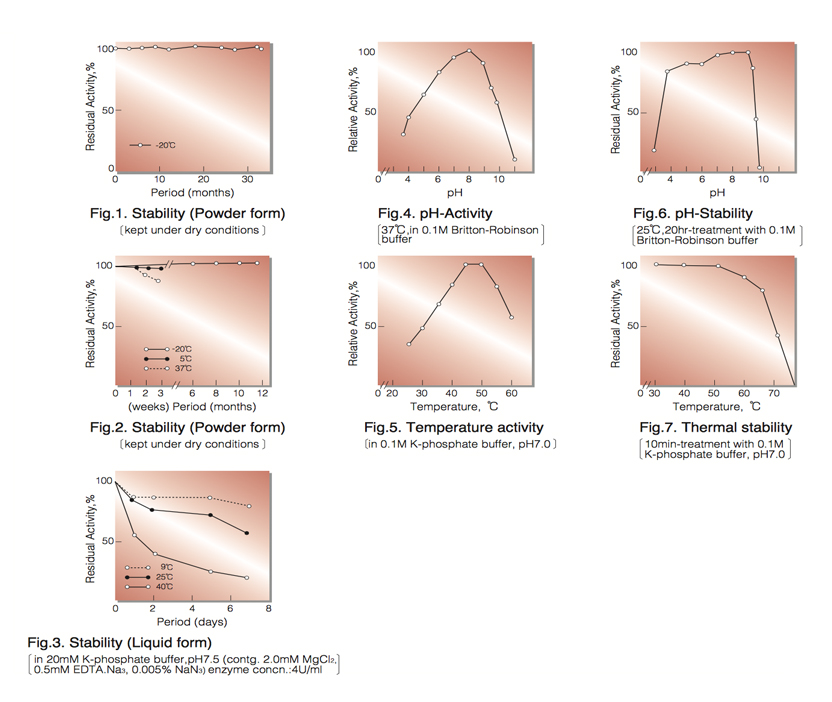

| Stability: | Stable at -20°C for at least Two years (Fig.1) |

|---|---|

| Molecular weight : | approx. 134,000 |

| Isoelectric point: | 5.95±0.05 |

| Inhibitors : | Hg⁺⁺, Ag⁺, ionic detergents |

| Optimum pH : | 7.0-9.0(Fig.4) |

| Optimum temperature : | 45-50°C(Fig.5) |

| pH Stability : | pH 7.0-9.0 (25°C, 20hr)(Fig.6) |

| Thermal stability : | below 55°C (pH 7.0, 10min)(Fig.7) |

| Substrate specificity : | (Table 1) |

| Effect of various chemicals : | (Table 2) |

APPLICATIONS

This enzyme is useful for enzymatic determination of triglyceride in serum when coupled with L-α- glycerophosphate oxidase (G3O-321) and glycerol kinase (GYK-301, GYK-311). Usually, the reaction can be completed in 5 minutes at 37°C by using 2.5〜3.0 units of the enzyme per test (3.0ml) at pH around 7.0.

ASSAY

Principle:

lipoprotein lipase

Triglyceride+3H₂O ► Glycerol+3 Fatty acid

glycerol kinase

Glycerol+ATP ► Glycerol-3-P+ADP

Mg++

L-α-glycerophosphate oxidase

Glycerol-3-P+O₂ ► Dihydroxyacetone-P+ H₂O₂

peroxidase

2H₂O₂+4-Aminoantipyrine+N,N-Diethyl-m-toluidine ► Quinoneimine dye + 4H₂O

The appearance of quinoneimine dye is measured at 545nm by spectrophotometry.

Unit definition:

One unit causes the formation of one micromole of glycerol (half a micromole of quinoneimine dye) per minute under

the conditions described below.

Method:

| A. Olive oil emulsion: | Sonicate the mixture of 5.0g of olive oil[reagent grade (highly refined, low acidity)]and 5.0ml of 5.0% Triton X-100 solution (B) for 10 minutes (20KHz). To the oil emulsion, add 25ml of 4.0% BSA solution (C) and 15ml of 0.1M K- phosphate buffer, pH 7.0 (D), and mix. (Should be prepared freshly) |

|---|---|

| B. Triton X-100 solution: | 5.0% (5.0ml Triton X-100/100ml of H₂O) |

| C. BSA solution: | 4.0% [4.0g bovine serum albumin/100ml of H₂O] |

| D. K-phosphate buffer, pH 7.0: | 0.1M |

| E. TCA solution: | 0.2M (33g trichloroacetic acid/1,000ml of H₂O) |

| F. MES-NaOH buffer: | 50mM MES buffer, pH 6.5 [Dissolve 9.76g of 2-(N-morpholino)-ethanesulfonic acid (MW=195.23) in ca. 850ml of H₂O and, after adjusting the pH to 6.5 with 5.0N NaOH, fill up to 1,000ml with H₂O] |

| G. Color developing reagent : | Dissolve the following chemicals and enzymes into 200ml of 50mM MES buffer

(F) in the following order: 4.0 ml Triton X-100 solution (B) 0.04 ml N,N-Diethyl-m-toluidine (Stir until completly dissolved) 4.0 mg 4-Aminoantipyrine 24.2 mg ATP・Na₂・3H₂O 40.7 mg MgCl₂・6H₂O 200 units Glycerol kinase (Toyobo, GradeⅢ) 500 units L-α-Glycerophosphate oxidase (Toyobo,GradeⅢ) 300 units Peroxidase (Purpurogallin units)(Toyobo, GradeⅢ) (Stable for one week if stored at 4°C in a brownish bottle) |

| F. Enzyme diluent: | 20mM K-phosphate buffer, pH 7.5 containing 2.0mM MgCl₂ and 0.5mM EDTA-Na₃ |

Procedure

| Concentration in assay mixture | |

|---|---|

| K-Phosphate buffer | 29.1 mM |

| Olive oil | 90.9mg/ml |

| MgCl₂ | 0.18 mM |

| Triton X-100 |

9.1 % |

| EDTA | 45 µM |

| BSA | 1.8 % |

(1st step)

1. Pipette 2.0ml of olive oil emulsion (A) into a test tube and equilibrate at 37°C for about 5 minutes.

2. Add 0.2ml of the enzyme solution* and mix.

3. After exactly 15 minutes at 37°C, add 2.0ml of TCA solution (E)

to stop the reaction and remove the precipitate by filtration

through filter paper.

(2nd step)

4. Pipette 0.05ml of the filtrate thus obtained into a test tube.

5. Add 3.0ml of color developing reagent (G) and incubate at 37°C for 15 minutes.

6. Measure the optical density at 545nm against water (OD test).

At the same time, prepare the blank by first mixing 2.0ml of the olive oil emulsion (A) after 15min- incubation at 37°C with 2.0ml of TCA solution, followed by the addition of the enzyme solution (1st step). By using the filtrate obtained from the mixture, carry out the 2nd step using the same procedure as the test and measure the optical density at 545nm (OD blank).

* Dissolve the enzyme preparation in ice-cold enzyme diluent (H) and dilute to 0.4−1.2U/ml with the same buffer, immediately before assay.

Calculation

Activity can be calculated by using the following formula :

ΔOD (OD test-OD blank)×Vt-1×Vt-2×df

Volume activity (U/ml) = = ΔOD×6.057×df

28.2×1/2×1.0× t ×Vs-1×Vs-2

Weight activity (U/mg)=(U/ml)×1/C

- Vt-1

- : Total volume in 1st step (4.2ml)

- Vt-2

- : Total volume in 2nd step (3.05ml)

- Vs-1

- : Sample volume in 1st step (0.2ml)

- Vs-2

- : Sample volume in 2nd step (0.05ml)

- 28.2

- : Millimolar extinction coefficient of quinoneimine dye under the assay condition (㎠/micromole)

- 1/2

- : Factor based on the fact that one mole of H₂O₂ produces half a mole of quinoneimine dye

- 1.0

- : Light path length (cm)

- t

- : Reaction time in 1st step (15 minutes)

- df

- : Dilution factor

- C

- : Enzyme concentration in dissolution (c mg/ml)

REFERENCES

- T.Saiki, Y.Takagi, T.Suzuki, T.Narasaki, G.Tamura and K.Arima; Agric. Biol. Chem. (Tokyo), 33, 414 (1969).

- T.Yamaguchi, N.Muroya, M.Isobe and M.Sugiura; Agric. Biol. Chem. (Tokyo), 37, 999 (1973).

| Substrate | Relative activity(%) | Substrate | Relative activity(%) |

|---|---|---|---|

| Olive oil | 94 | Tricaprylin (8 :0) | 64 |

| Triolein (18 :1) | 100 | Tricaproin (6 :0) | 2 |

| Tripalmitin (16 :0) | 2 | Tributyrin (4 :0) | 2 |

| Trimyristin (14 :0) | 7 | Tripropionin (3 :0) | 2 |

| Trilaurin (12 :0) | 4 | Triacetin (2 :0) | 1 |

| Tricaprin (10.0) | 17 |

Number of carbon atoms to number of double bonds is given in parenthesis.

| Chemical | Concn.(mM) | Residual activity(%) |

Chemical | Concn.(mM) | Residual activity(%) |

|---|---|---|---|---|---|

| None | − | 100 | PCMB | 2.0 | 100 |

| CaCl₂ | 2.0 | 95 | MIA | 2.0 | 98 |

| Ba(OAc)₂ | 2.0 | 92 | NaF | 20.0 | 95 |

| FeCl₃ | 2.0 | 80 | NaN₃ | 20.0 | 97 |

| CoCl₂ | 2.0 | 90 | EDTA | 5.0 | 100 |

| MnCl₂ | 2.0 | 85 | o-Phenanthroline | 2.0 | 100 |

| Zn(OAc)₂ | 2.0 | 86 | α,α′-Dipyridyl | 2.0 | 94 |

| NiCl₂ | 2.0 | 97 | Borate | 20.0 | 100 |

| Pb(OAc)₂ | 2.0 | 80 | Triton X-100 | 1.0% | 100 |

| AgNO₃ | 2.0 | 47 | Brij 35 | 1.0% | 100 |

| HgCl₂ | 2.0 | 5 | SDS | 0.1% | 4 |

| CdCl₂ | 1.0 | 82 | Tween 20 | 0.1% | 89 |

| CrCl₂ | 1.0 | 42 | Span 20 | 0.1% | 100 |

| SnCl₂ | 1.0 | 49 | Na-cholate | 1.0% | 93 |

| CuSO₄ | 1.0 | 58 | Taurocholate | 0.1% | 100 |

| NEM | 2.0 | 98 |

Ac, CH₃CO; NEM, N-Ethylmaleimide; PCMB, p-Chloromercuribenzoate; MIA, Monoiodoacetate; EDTA, Ethylenediamineteraacetate; SDS, Sodium dodecyl sulfate.

To get a quote, contact us at info@toyobousa.com, or INQUIRY.